Product Showcase

Precision Machinery, Intelligent Future – Hankun Intelligent delivers efficient and reliable industrial solutions for you.

Product Showcase

Fully Automatic Servo Tapping Machine

Polishing Machines

Feeding Machines

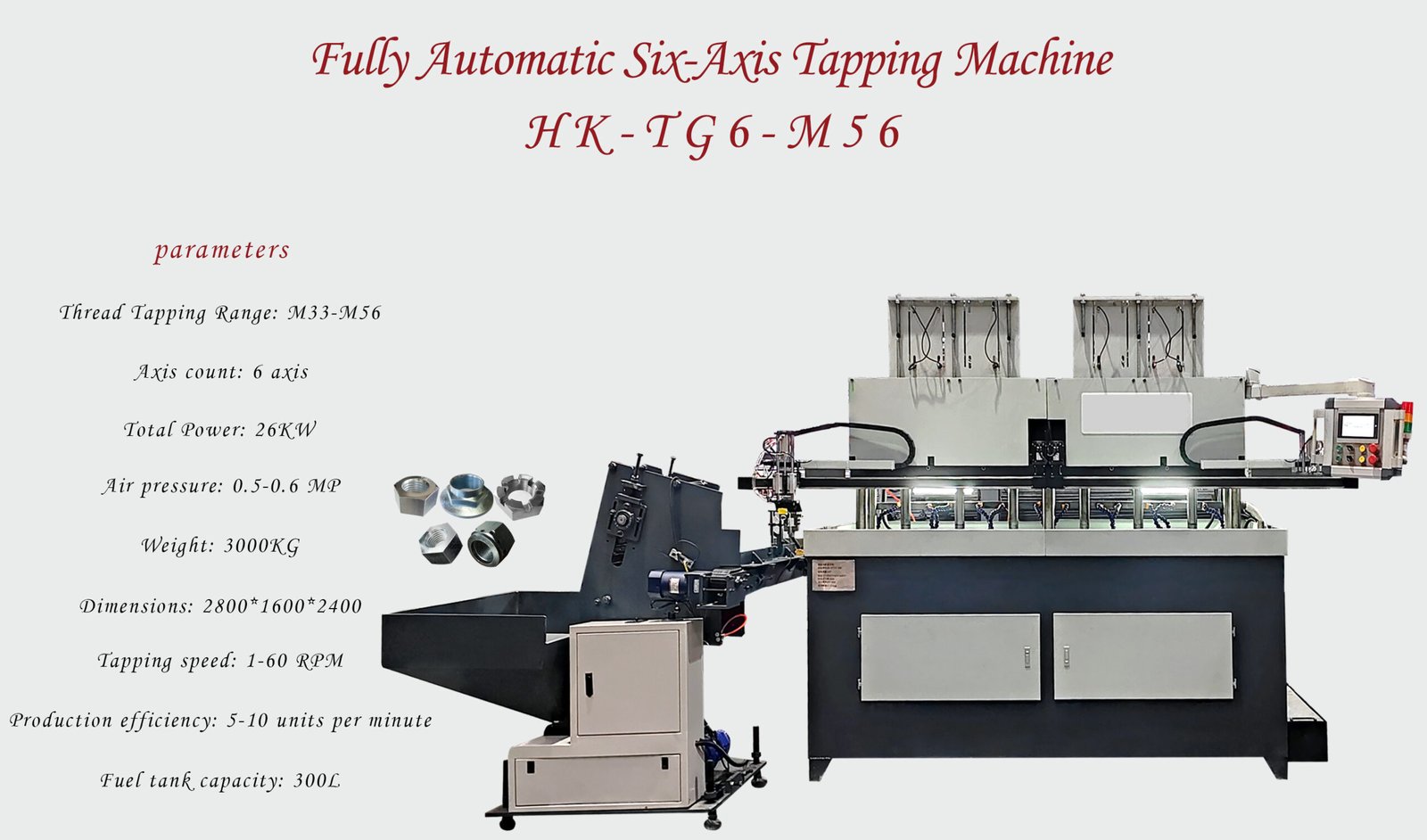

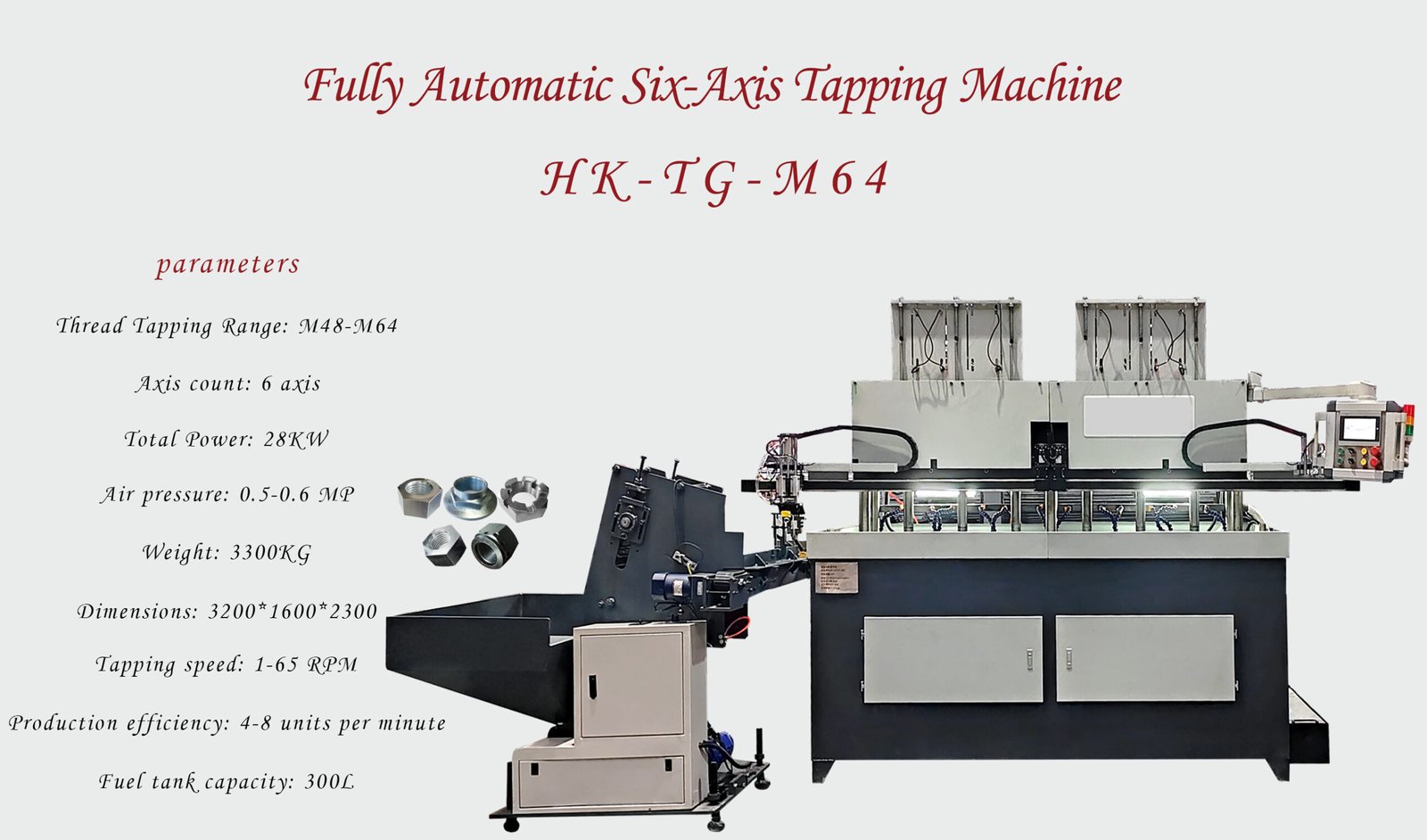

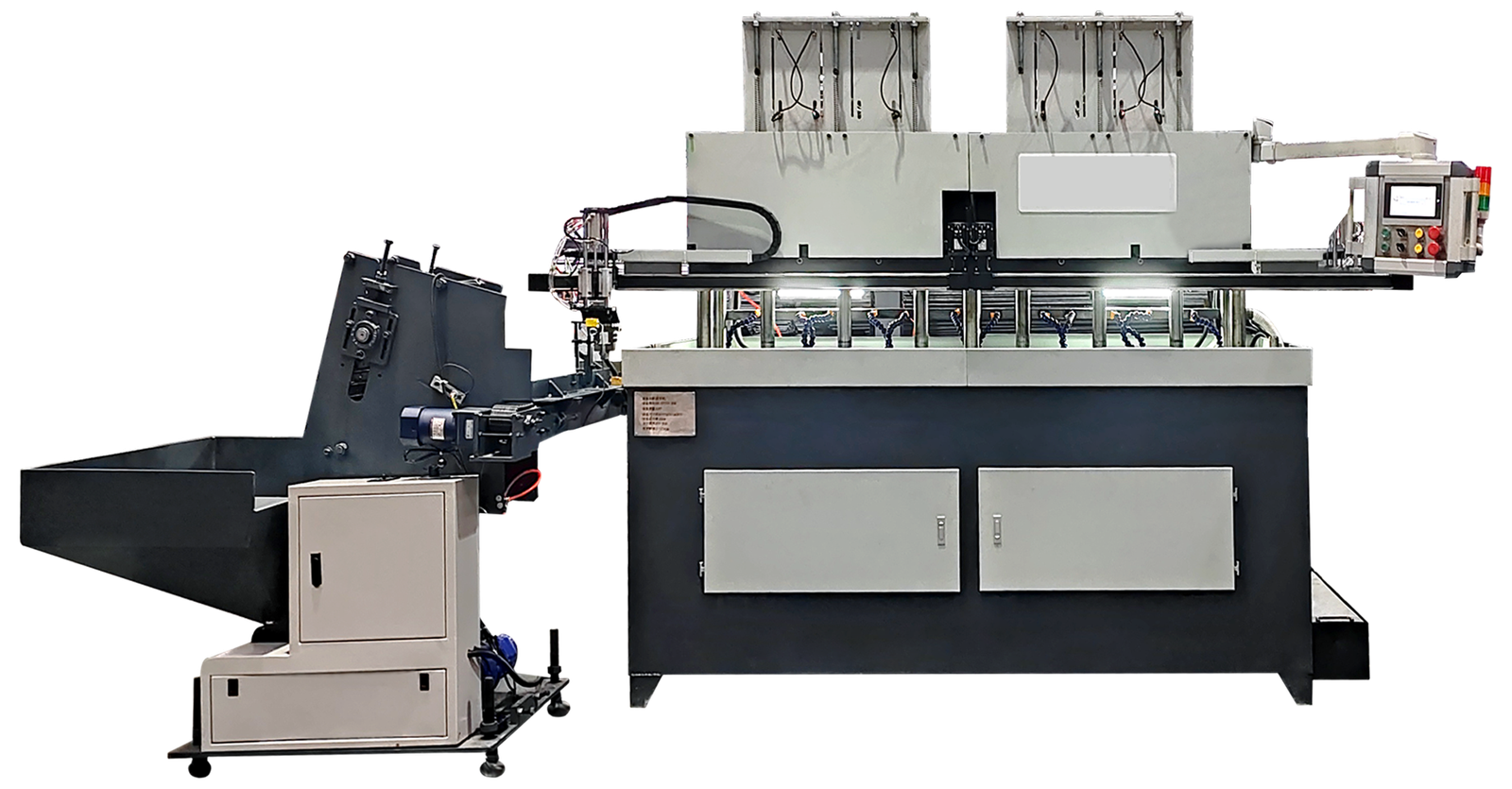

Fully Automatic

Six-Spindle

Tapping Machine

Hankun Intelligent Tapping Machine: Tapping, Reaming, Chamfering – All in One Step.

Hankun Intelligent’s high-efficiency tapping machines combine precision, speed, and versatility. Ideal for precision parts and complex workpieces, they boost productivity, meet diverse needs, and enhance your market edge.

Product Details

Hankun Intelligent Tapping Machines are designed for efficient and precise thread processing. Whether for precision parts or complex workpieces, our machines handle them with ease, significantly boosting your productivity and reducing operational costs. Choose Hankun Intelligent for flawless threads and a powerful boost to your manufacturing operations!

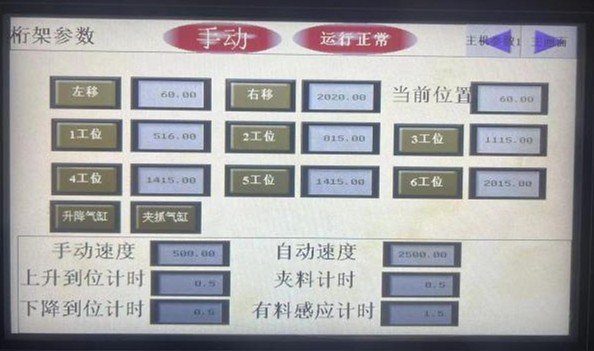

Plug-in 7-inch IoT Touchscreen: Scan the QR code to download the mobile control app, enabling remote data monitoring and equipment control.

Fully digital control allows setting current upper/lower limits for different products to protect tools. Each spindle can preset and monitor real-time production counts, ensuring quantitative production and scheduled tap replacement.

- For different product specifications and tool changes, the tapping speed can be customized as needed to ensure optimal cutting speeds for various specifications, protecting thread quality and taps. The timing of coordinated actions can also be adjusted based on actual conditions.

- Thread pitch can be freely adjusted for different product specifications, with forward/reverse tapping switchable. Features include quantitative production stop alarm and fine-tuning of timing coordination across production stages. All 6 workstations support independent parameter settings

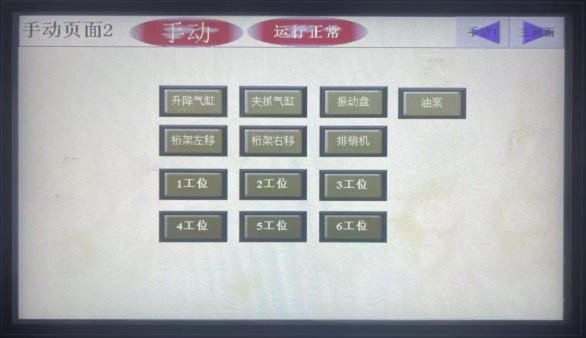

- Multiple functions integrated into one system. All cylinders, oil pumps, and gantry manipulators feature digital independent switches and fine-tuning jog controls for easy adjustment.

- Equipped with real-time I/O monitoring to visually identify the cause of equipment abnormalities, enabling direct troubleshooting and reducing demands on workers’ expertise and workload.

More Product Details of Tapping Machine

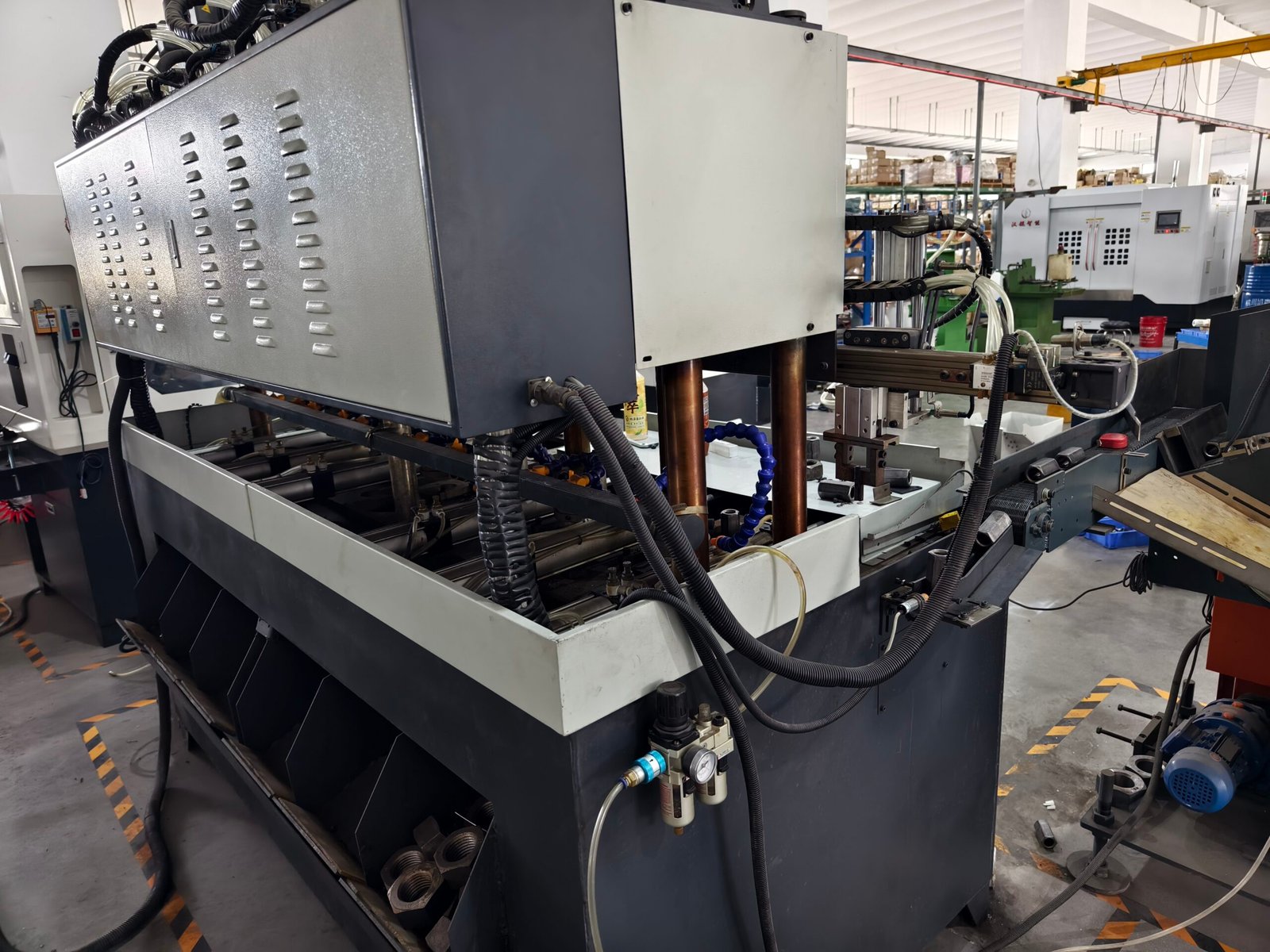

Discharge position: The discharge chute adopts a scrap iron and workpiece separation structure design, effectively preventing mixing of scrap and workpieces. Some areas are equipped with damping pads to significantly reduce noise from workpiece collisions with the material bin.

Robotic Feeding Mechanism :

The robotic arm performs reciprocating material pickup and feeding via servo motor drive, ensuring high positioning accuracy. The pickup gripper, driven by a cylinder, secures workpieces by expanding within inner holes, significantly improving compatibility range.

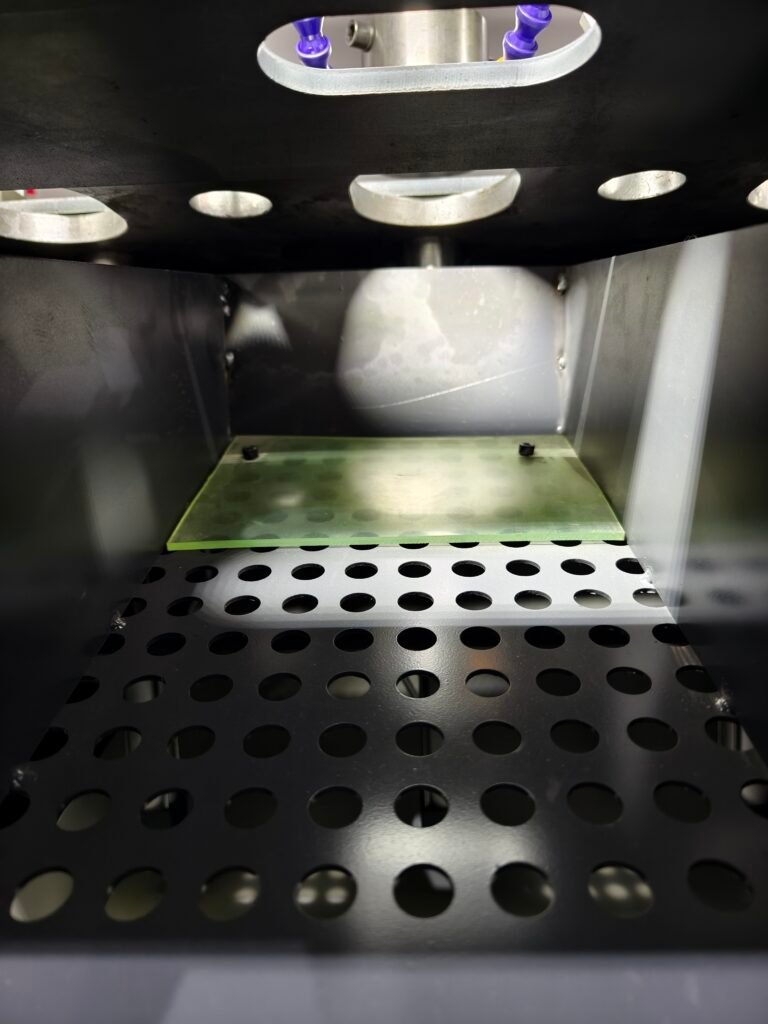

The chip collection tray: features a deepened center and sloped perimeter design, effectively gathering iron scraps pushed from above to reduce manual cleaning frequency and improve tapping efficiency. The sloped edges prevent splashing of tapping oil, minimizing environmental contamination and effectively containing oil within the machine body.

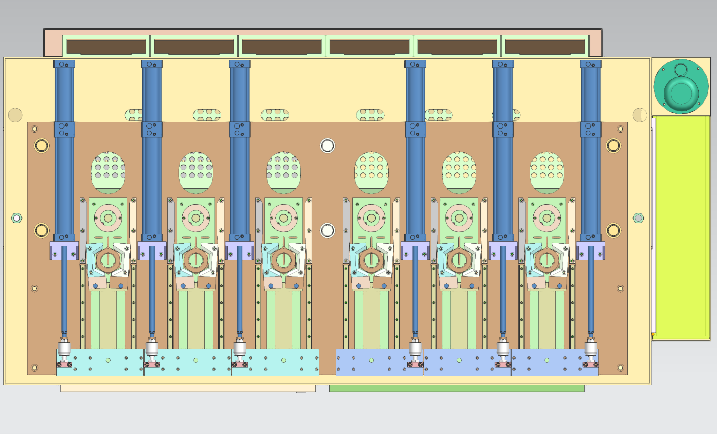

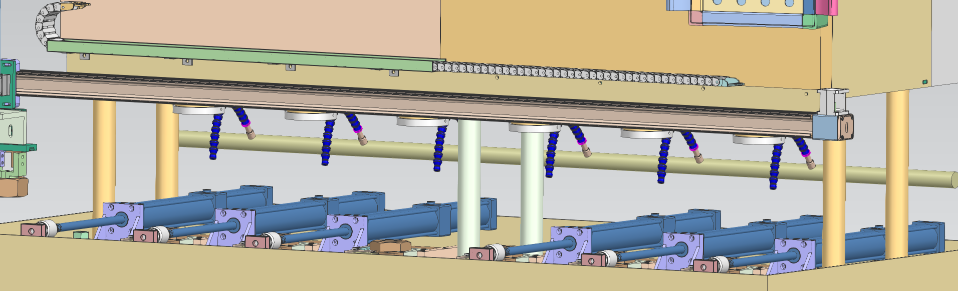

The main frame is constructed with high-strength steel plate welding, integrally ground for flatness, and processed through multi-stage stress relief treatment, achieving a platform flatness tolerance of ±0.02mm/m.

The platform is supported by six load-bearing columns to minimize gravitational deformation during operation, ensuring consistent tapping verticality accuracy.

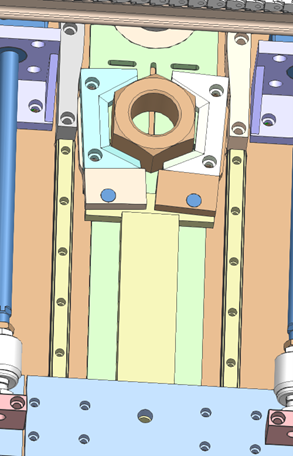

The fixture incorporates a compensation mechanism, allowing micro-adjustment for workpiece centering while maintaining margin. Ensures taps automatically locate the center, guaranteeing vertical tapping accuracy.

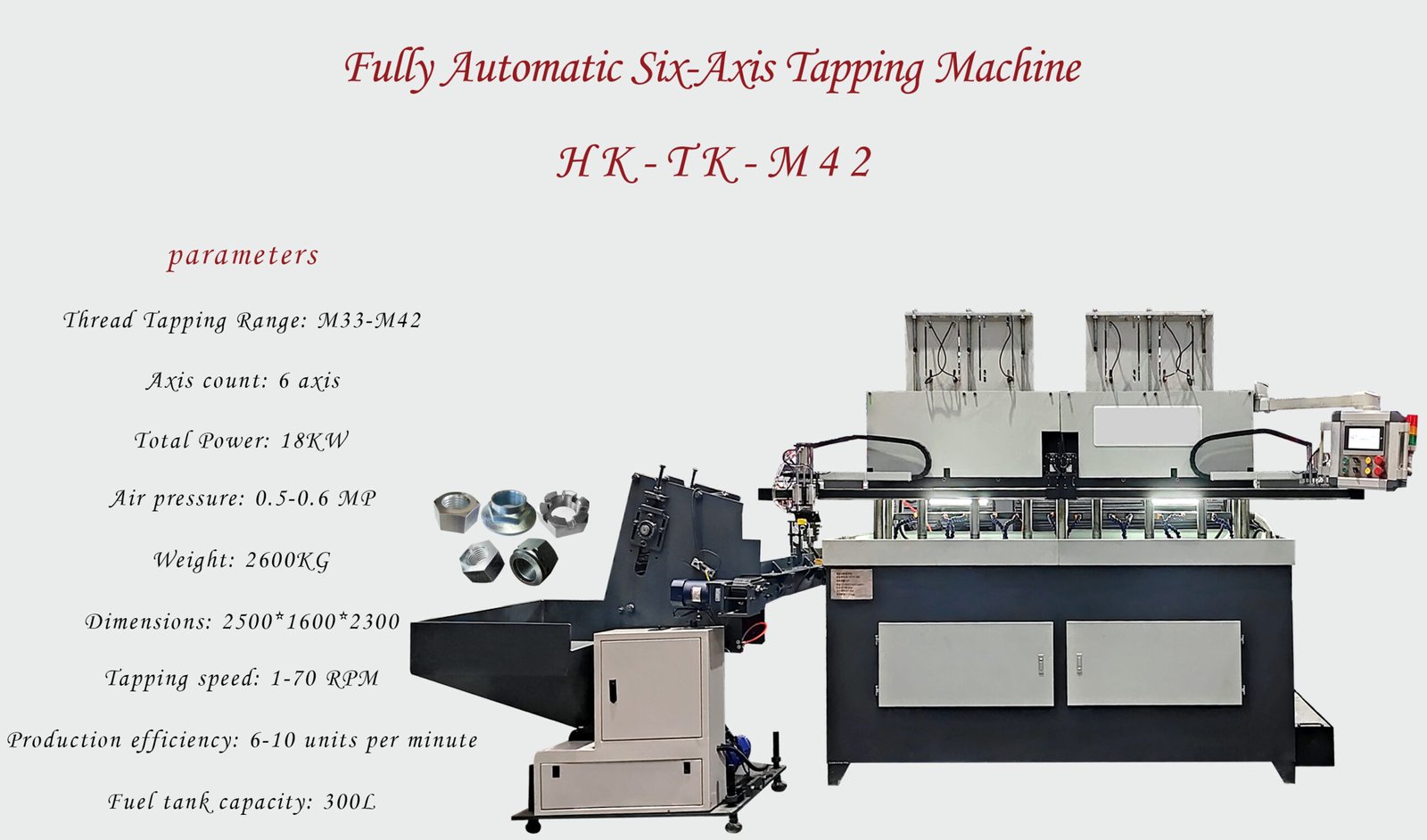

Technical Specifications of Han Kun Machine

- Tapping Range: M48-M64

- Axis Count: 6-axis

- Total Power: Approx. 28 KW

- Air Pressure: 0.5-0.6 MPa

- Weight: 3300 KG

- Dimensions (L x W x H): 3200 x 1600 x 2300 mm

- Tapping Speed: 1-65 RPM

- Production Efficiency: 5-10 pieces/minute

- Oil Tank Capacity: 300L

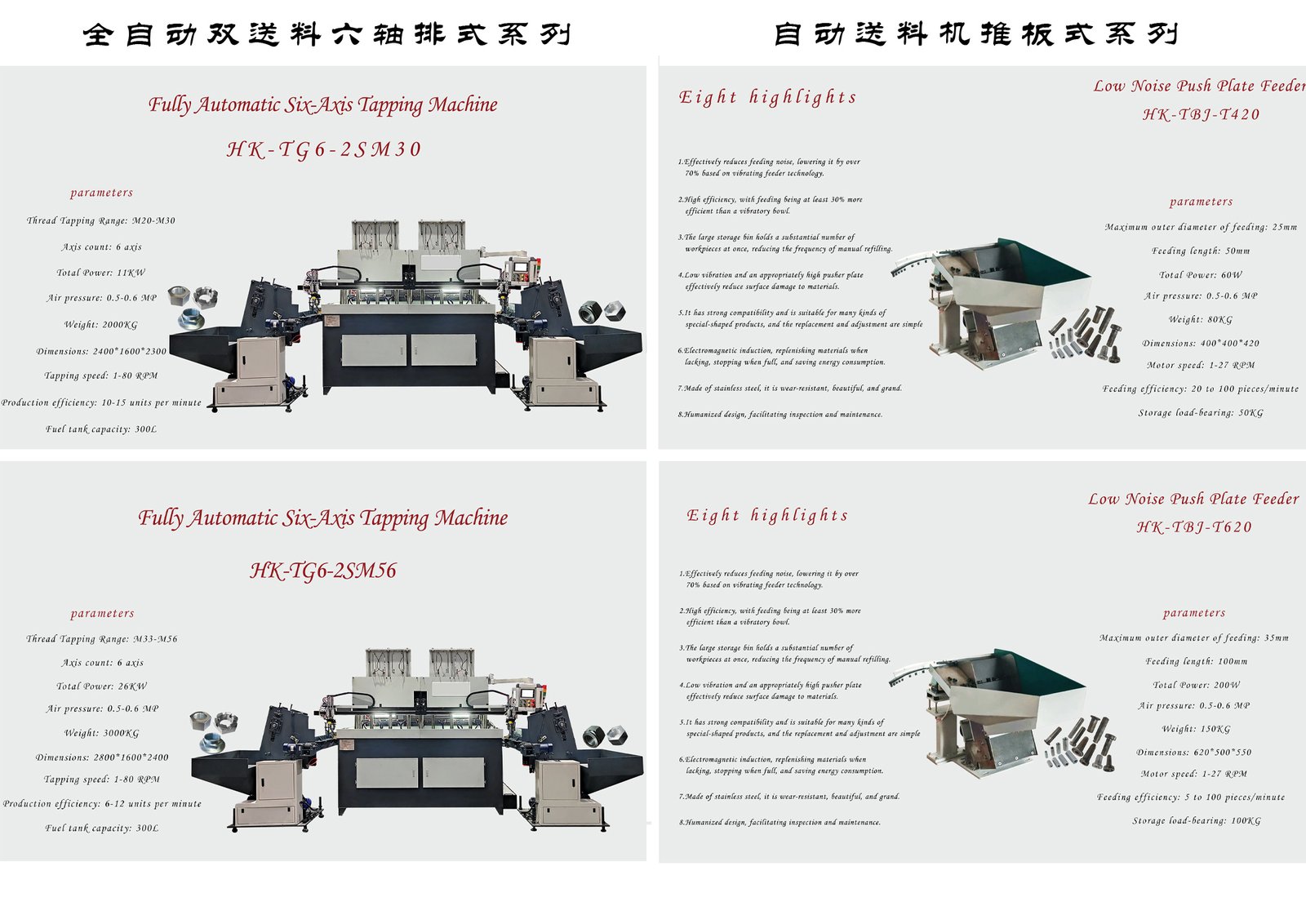

More Models Available