Product Showcase

Precision Machinery, Intelligent Future – Hankun Intelligent delivers efficient and reliable industrial solutions for you.

Product Showcase

Tapping Machines

Polishing Machines

Feeding Machines

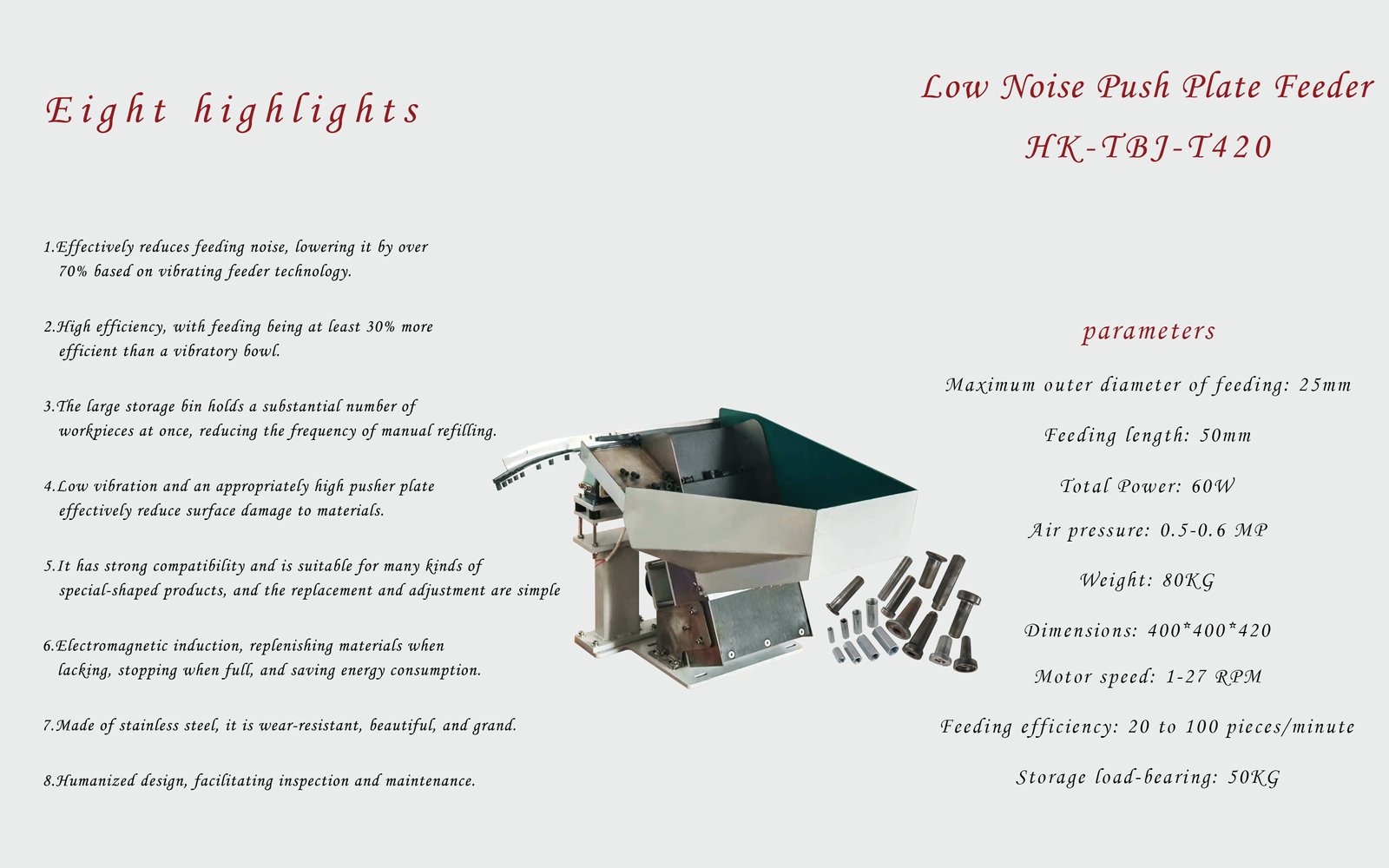

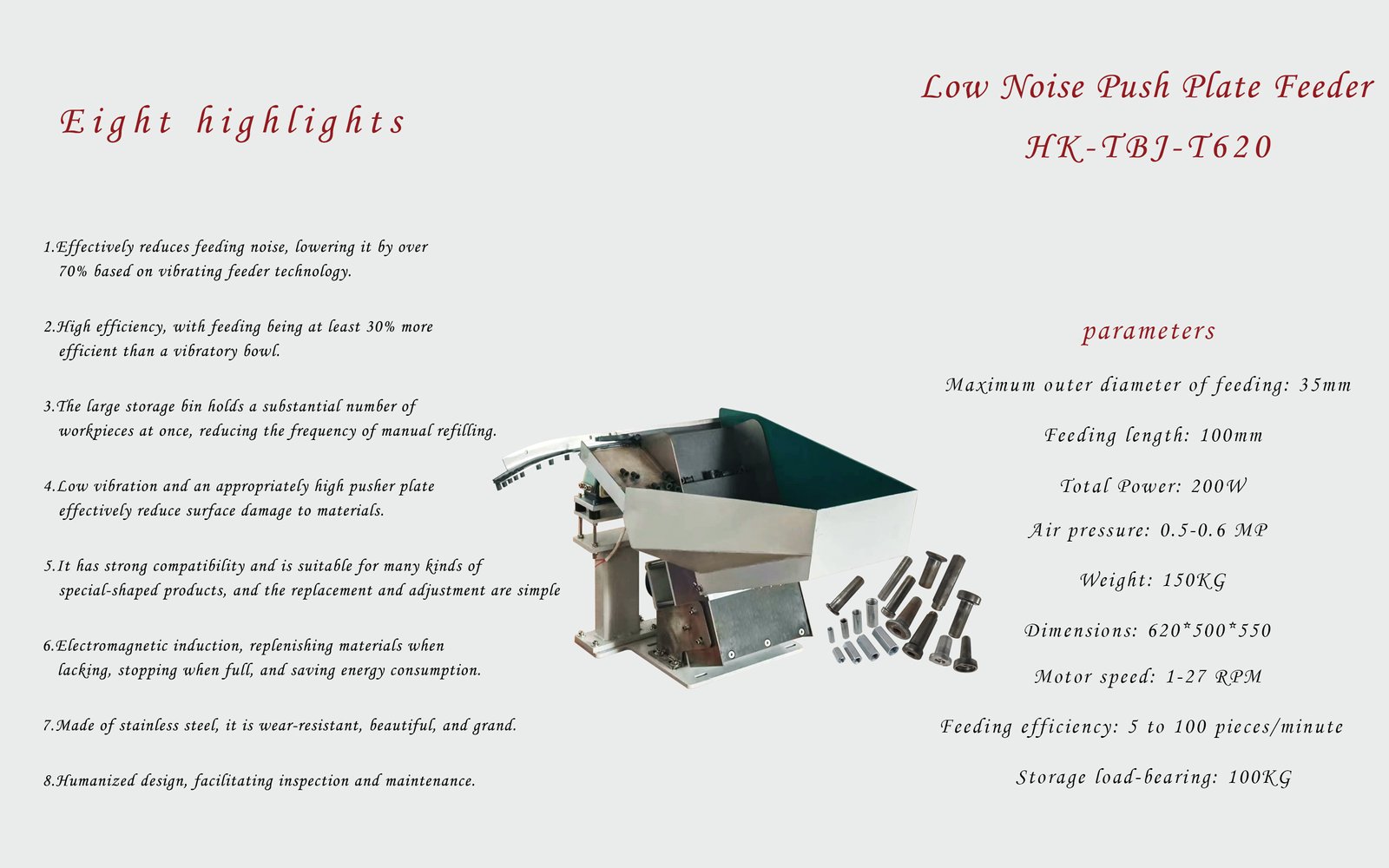

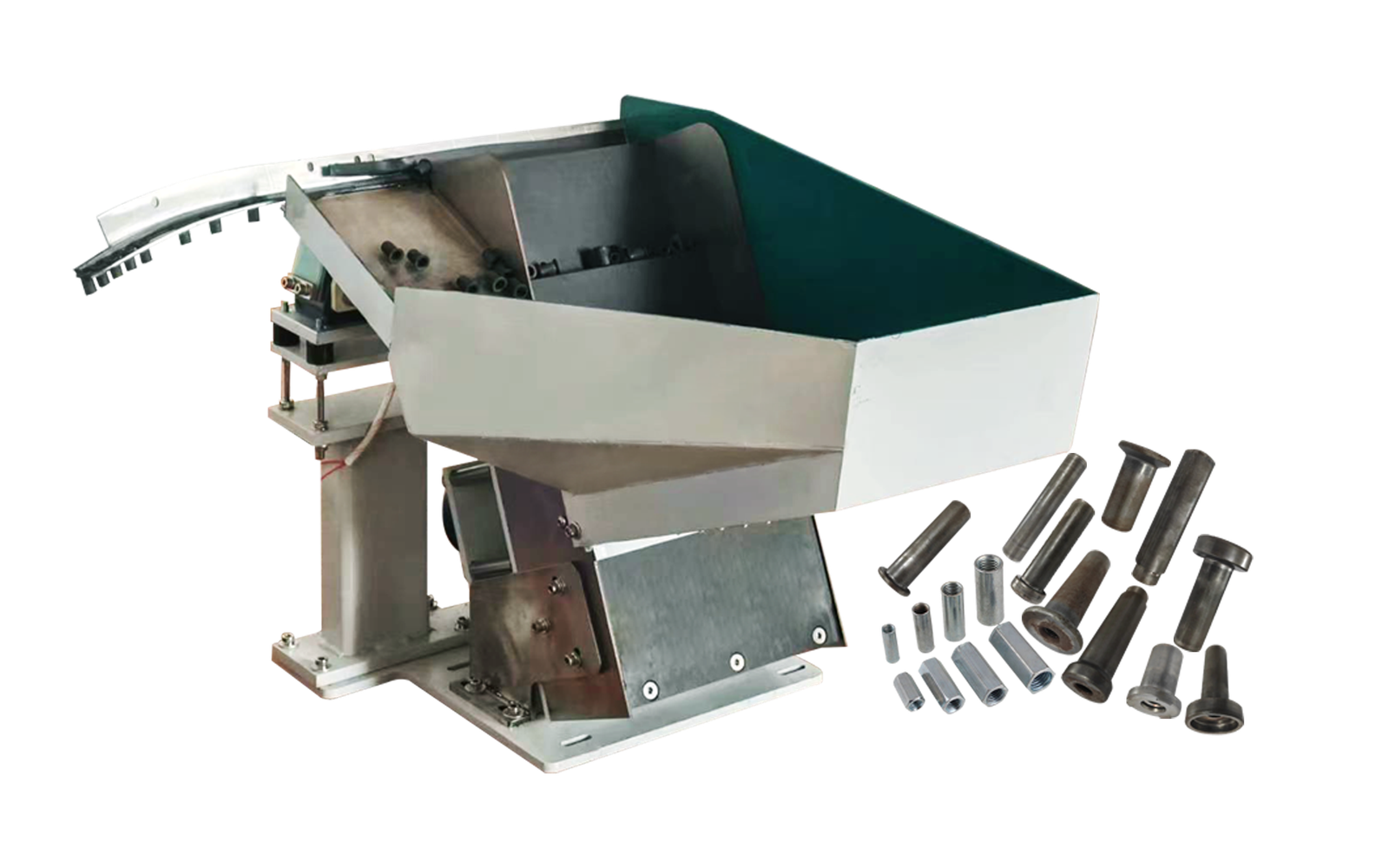

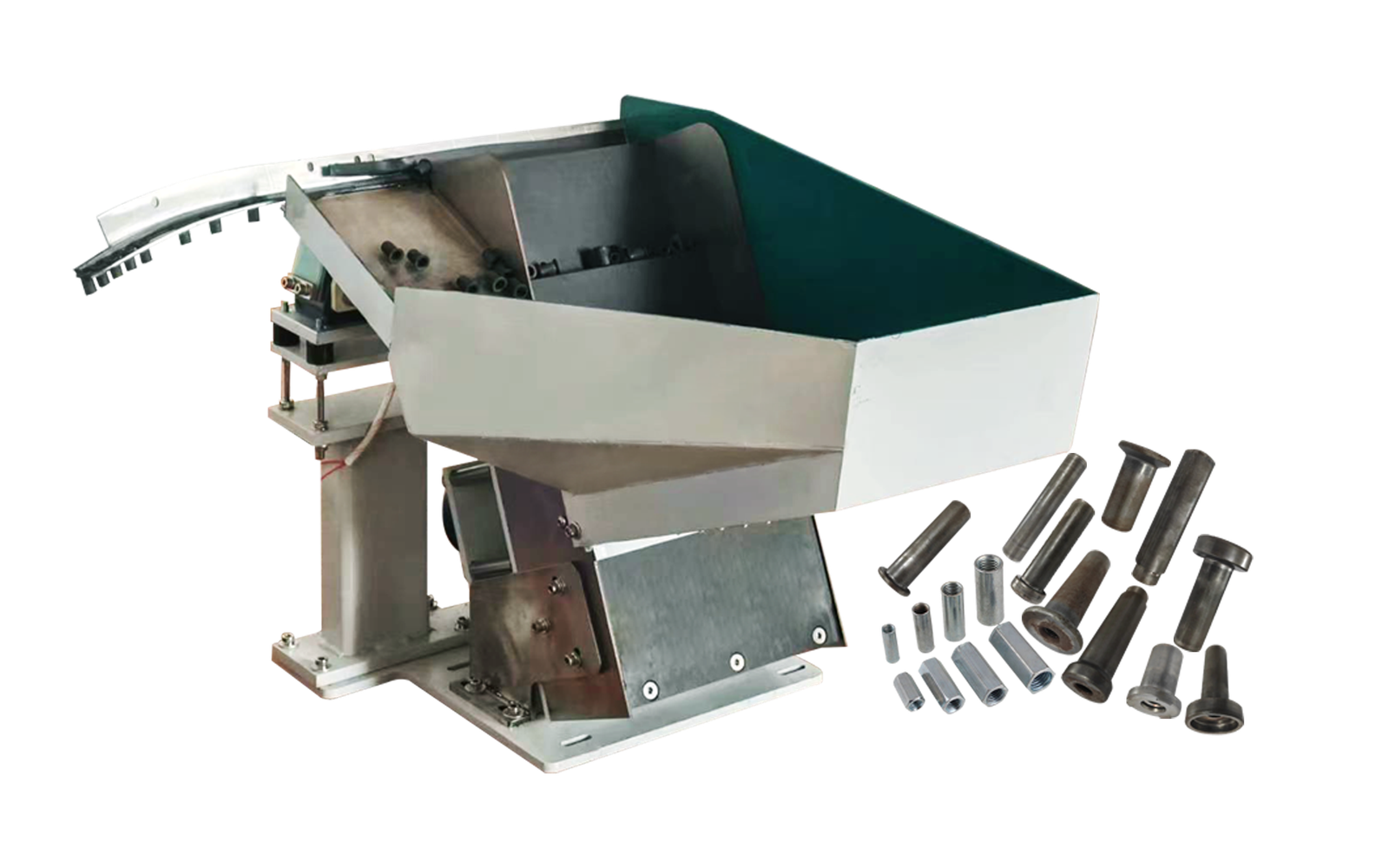

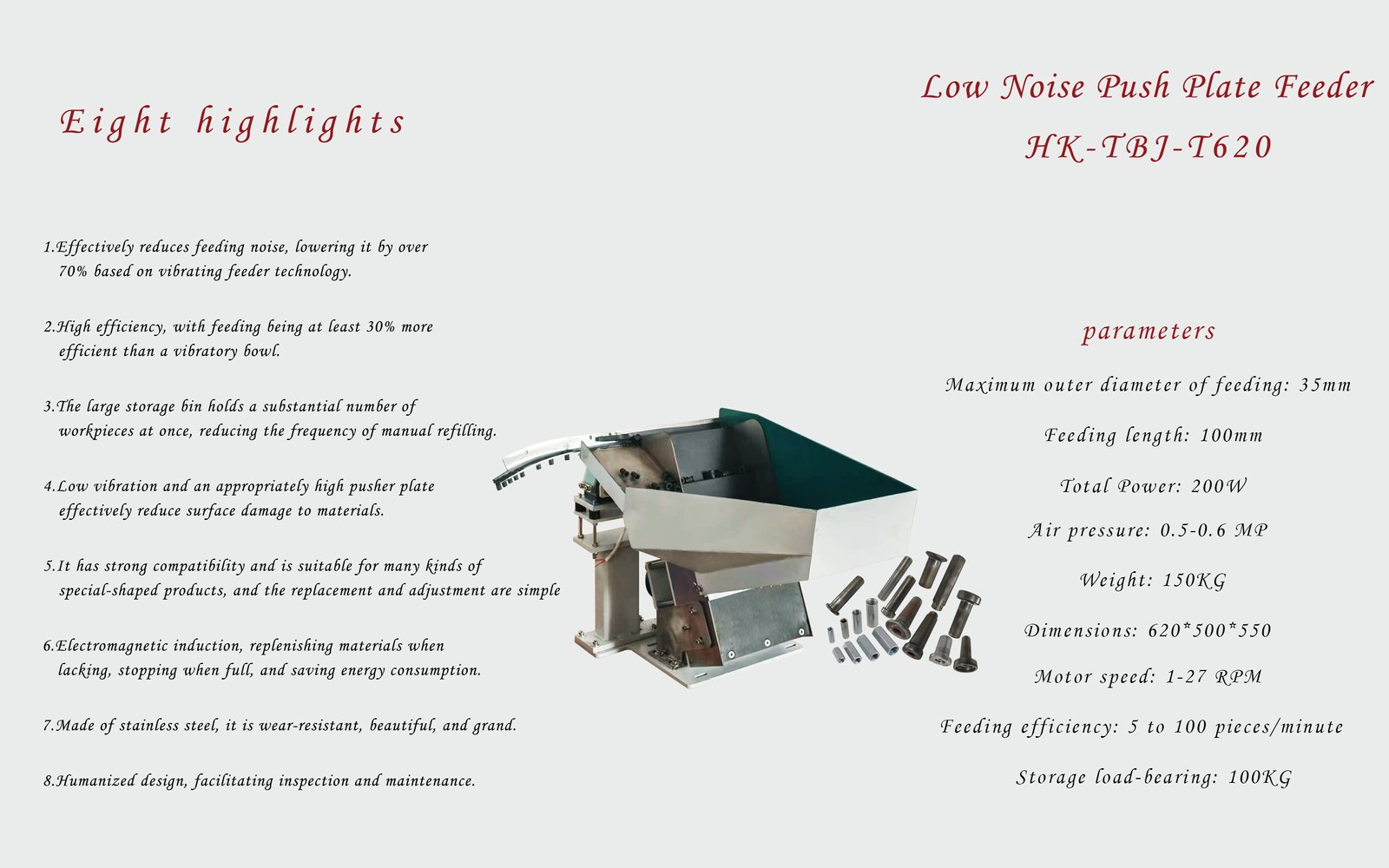

Low-Noise Push Plate Feeder

Hankun Low-Noise Push Plate Feeder: Efficient, Quiet, Reliable – Seamless Material Flow.

Hankun Intelligent’s Low-Noise Push Plate Feeders deliver efficient, quiet, and precise material handling. Engineered for high performance and versatility, they minimize noise, reduce material damage, and optimize workflow efficiency, seamlessly adapting to diverse production demands and boosting your competitive advantage in the industry.

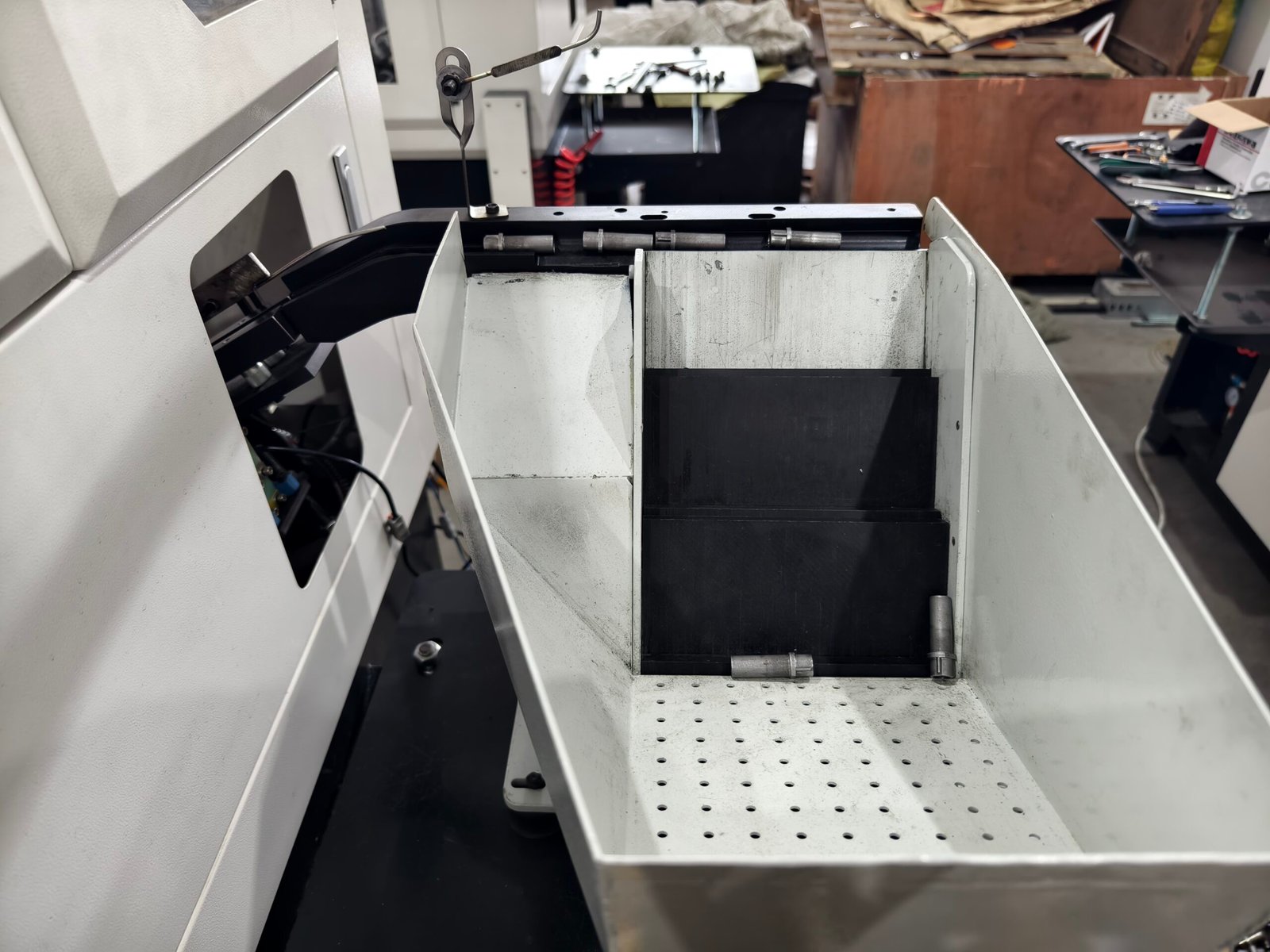

Product Details

Hankun Intelligent Low-Noise Push Plate Feeders are designed for quiet and efficient material handling. Whether for delicate parts or high-volume production, our feeders ensure smooth operation, reduce surface damage, and maximize workflow productivity. Choose Hankun Intelligent for advanced feeding solutions that elevate your production line to new heights!

Linear Vibrator Version

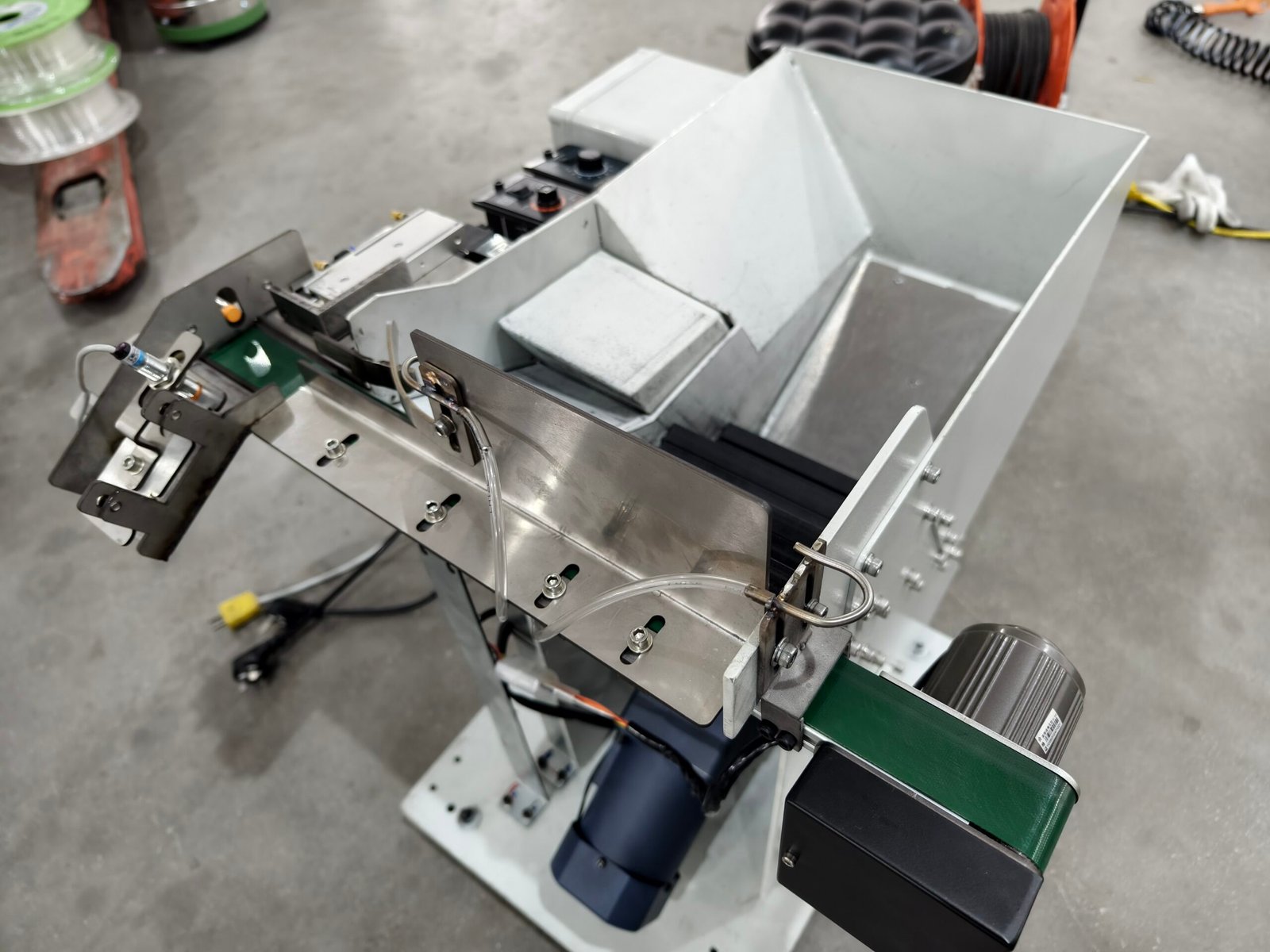

Belt Version

More Technical Specifications of Tapping Machine

8Core Advantages for Enhanced Production:

1. Effectively reduces feeding noise by more than 70% compared to traditional vibrating disc feeders.

2. High efficiency, with feeding speed at least 30% higher than that of vibrating disc feeders.

3. Large storage bin allows for one-time storage of a large number of workpieces, reducing the frequency of manual loading.

4. Low vibration design with an optimally adjusted push plate height, effectively minimizing surface damage to materials. Suitable for various types of non-similar products, with simple adjustment mechanisms.

5. Strong compatibility, saving energy consumption.

6. Optical-electromagnetic sensing for automatic material replenishment when empty and stopping when full.

7. Made of stainless steel, wear-resistant, aesthetically pleasing, and elegant.

8. Humanized design for easy inspection and maintenance.

Technical Specifications of Han Kun Machine

- Maximum Feeding Diameter: 35mm

- Feeding Length: 100mm

- Total Power: 200W

- Air Pressure: 0.5-0.6 MPa

- Weight: 150 KG

- Dimensions (L x W x H): 620 x 500 x 550 mm

- Motor Speed: 1-27 RPM

- Feeding Efficiency: 5-100 pieces/minute

- Storage Capacity: 100 KG

More Models Available