Product Showcase

Precision Machinery, Intelligent Future – Hankun Intelligent delivers efficient and reliable industrial solutions for you.

Product Showcase

Tapping Machines

Polishing Machines

Feeding Machines

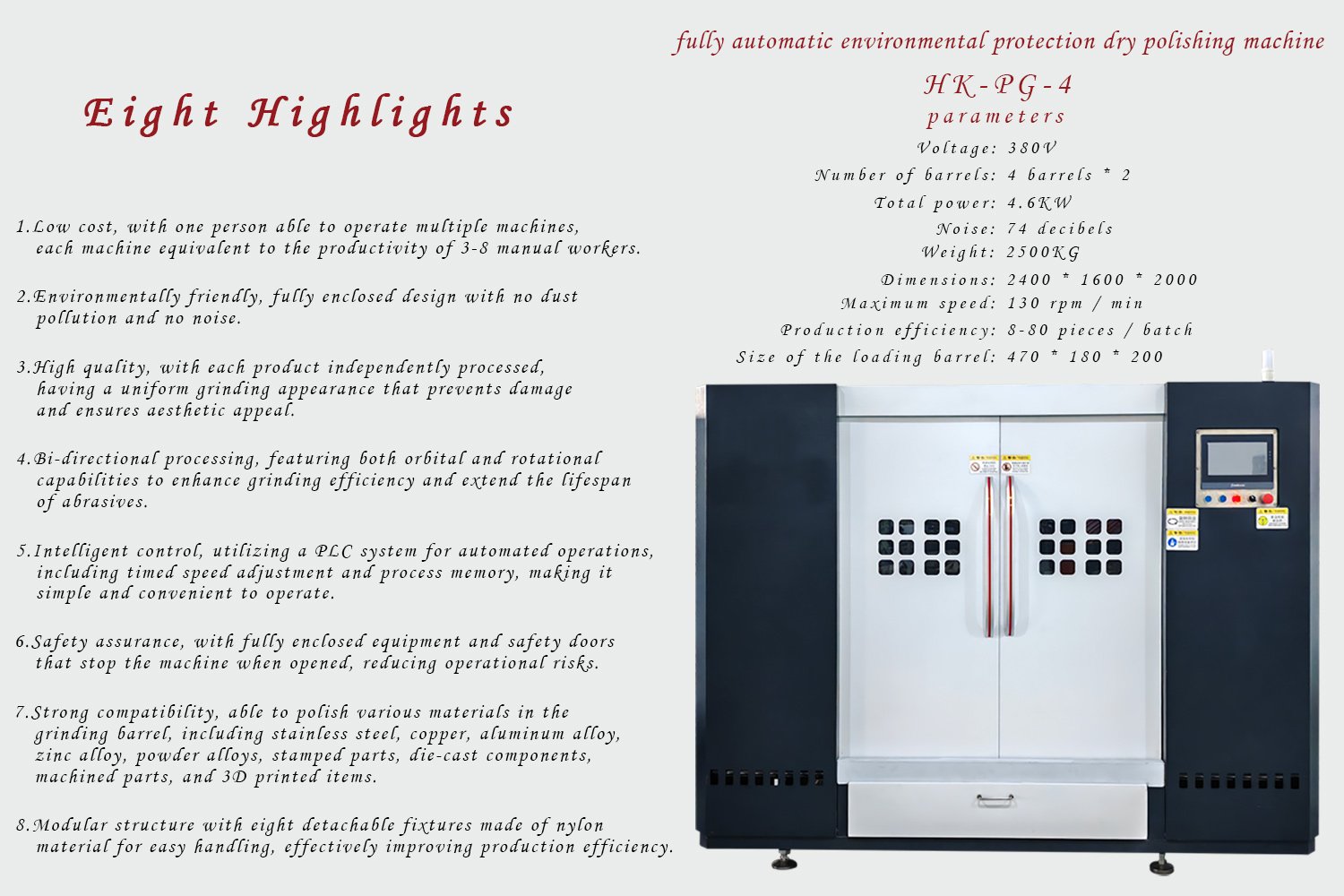

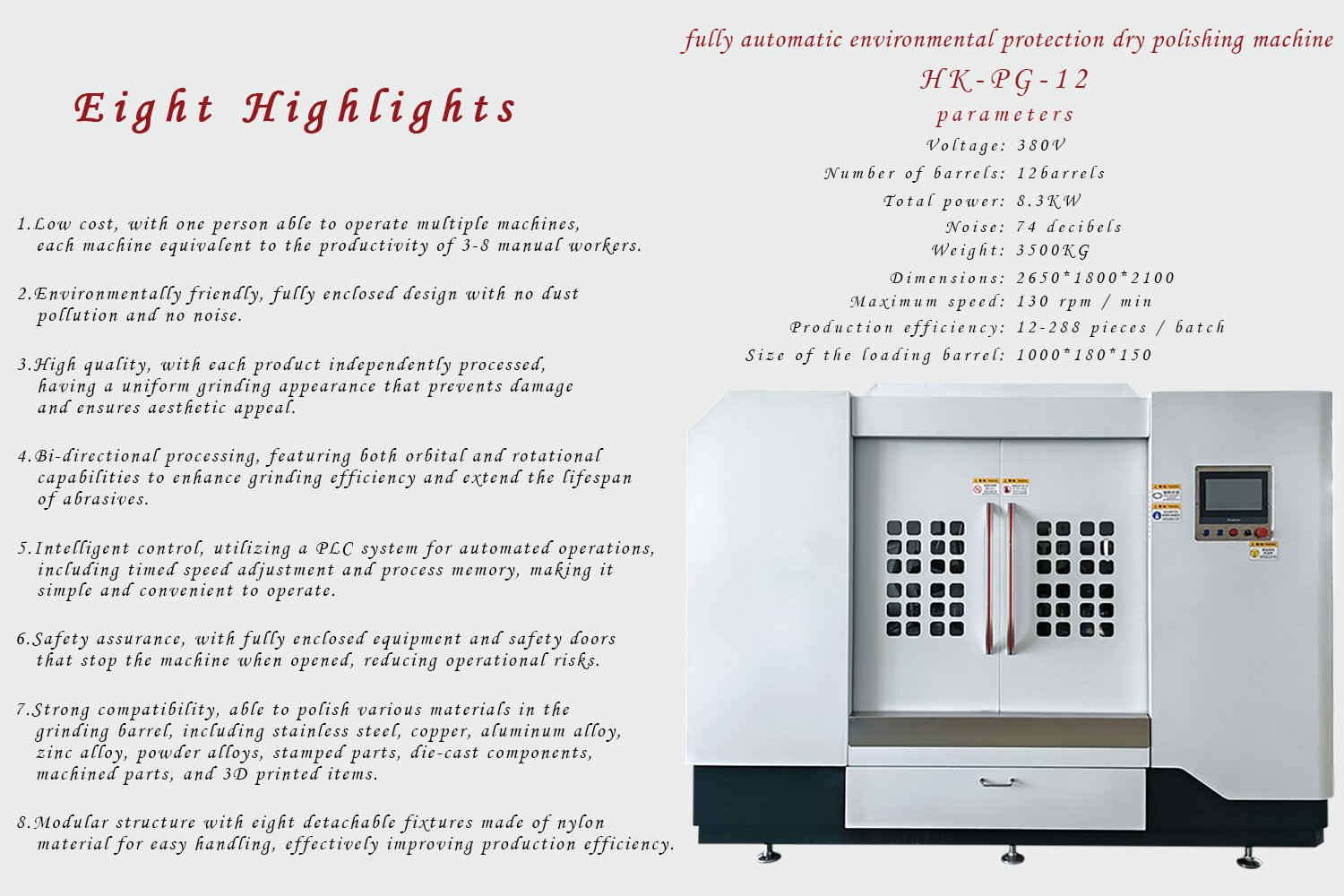

Fully Automatic Dry Polishing Machine

Environmentally Friendly Dry Grinding & Polishing Machine – An Efficient, Intelligent, and Pollution-Free Metal Surface Treatment Solution

Hankun Intelligent’s dry grinding and polishing machine adopts a fully enclosed design with PLC intelligent control, delivering high efficiency, low noise (<74 dB), and dust-free metal surface treatment. Its unique dual-motion grinding technology (revolution + rotation) enhances grinding efficiency while extending abrasive life. Compatible with stainless steel, copper, aluminum alloy, and various other materials, it meets the high standards of precision manufacturing. Featuring modular fixtures for easy operation, a single machine can replace 3-8 workers, making it the ideal choice for green and intelligent manufacturing.

Product Details

The Hankun Polishing Machine features a fully enclosed eco-friendly design with an intelligent PLC control system, supporting dry grinding processes. Equipped with dual-motion technology (revolution + rotation), it handles various metal materials including stainless steel, copper, and aluminum alloys. Operating at noise levels below 74 dB, the 12-barrel model can process 12-288 workpieces per batch. Its modular nylon fixture design ensures easy operation, delivering production efficiency equivalent to 3-8 workers.

Precision Grinding · Green Manufacturing

(The three types of abrasive media used:)

Rough grinding

Remove the knife marks and burrs

Fine grinding

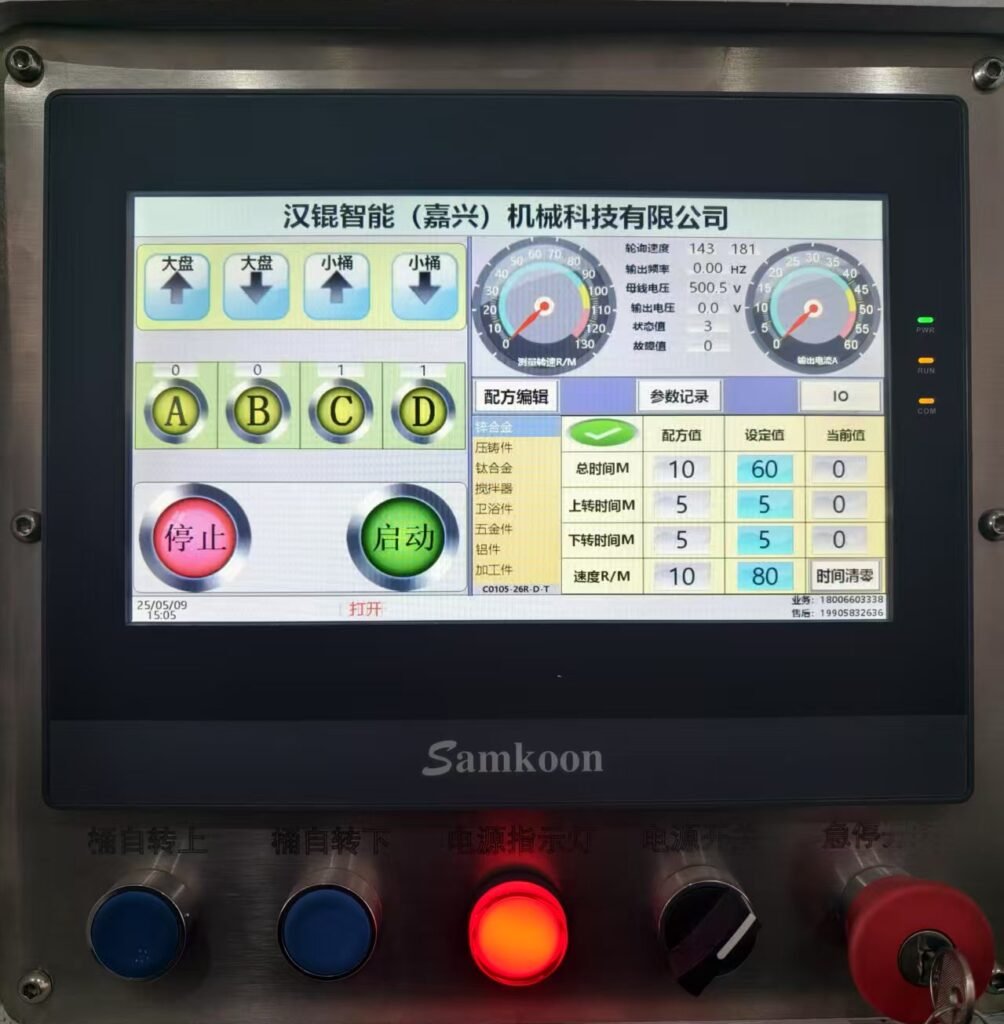

Plug-in 7-inch IoT Touchscreen: Scan the QR code to download the mobile control app, enabling remote data monitoring and equipment control.

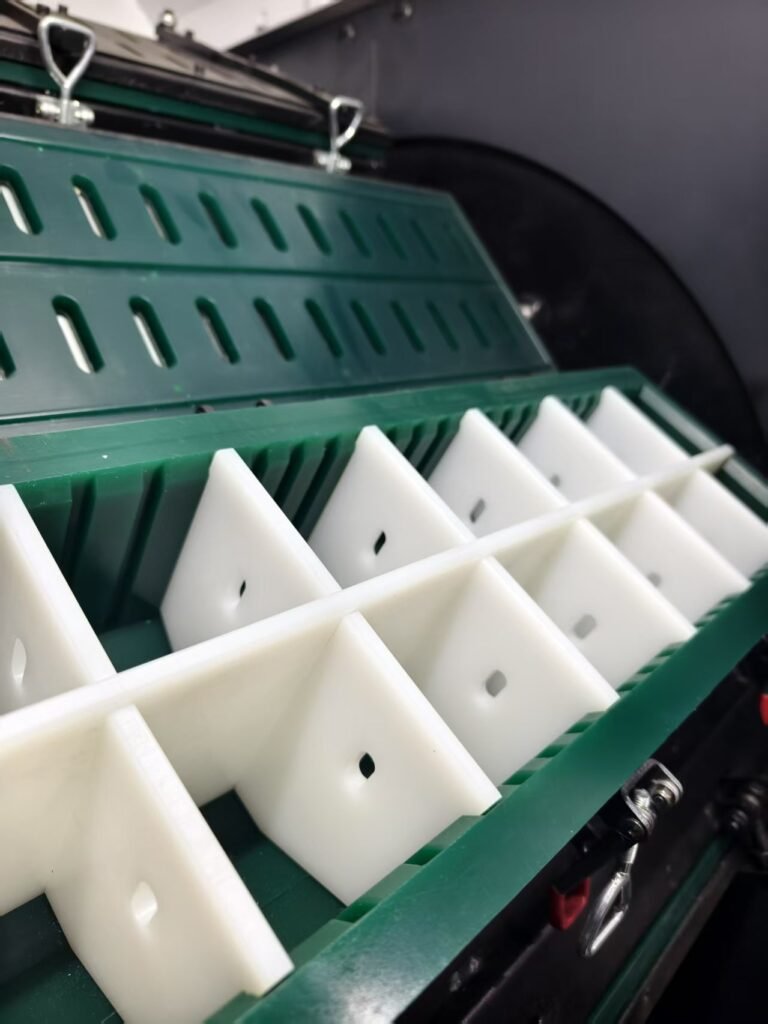

Multi-Spindle Rotational Polishing: Equipped with four spindles, each fitted with 1-3 polishing barrels. The dual rotation of spindles and barrels drives abrasives to grind and polish product surfaces.

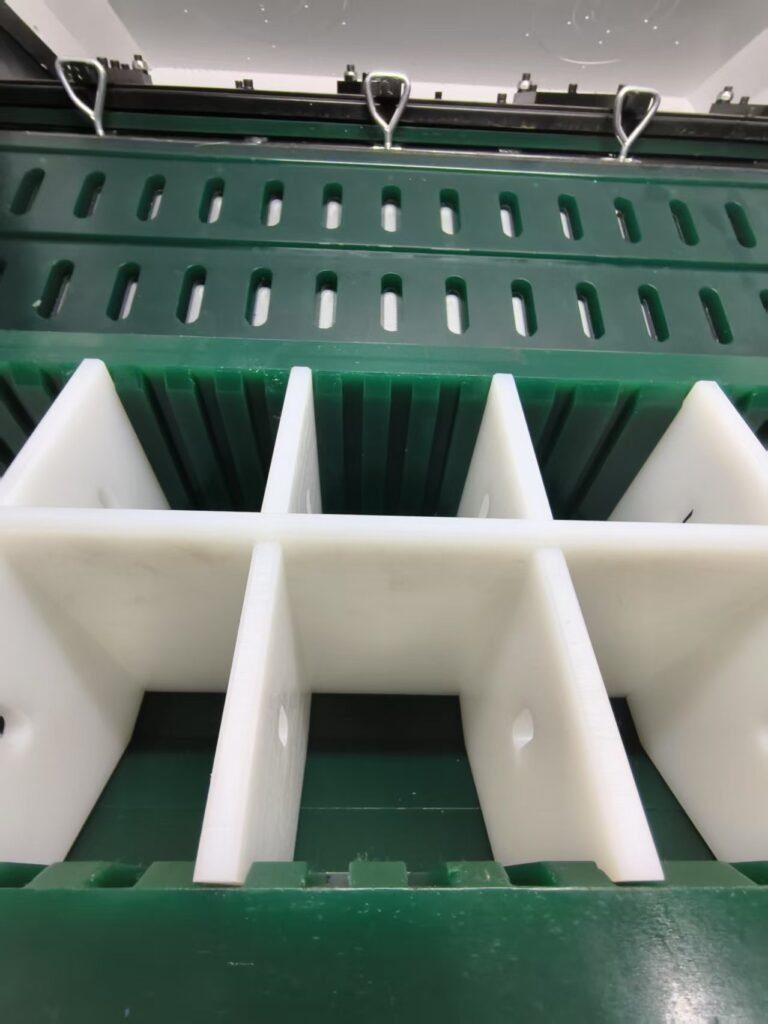

Adjustable Baffle Design: The barrels feature movable baffles to prevent product collisions and accommodate workpieces of different sizes.

Automatic Abrasive Replenishment: Small holes in the baffles allow abrasives (e.g., walnut shells) to flow through, automatically filling gaps in the polishing area.

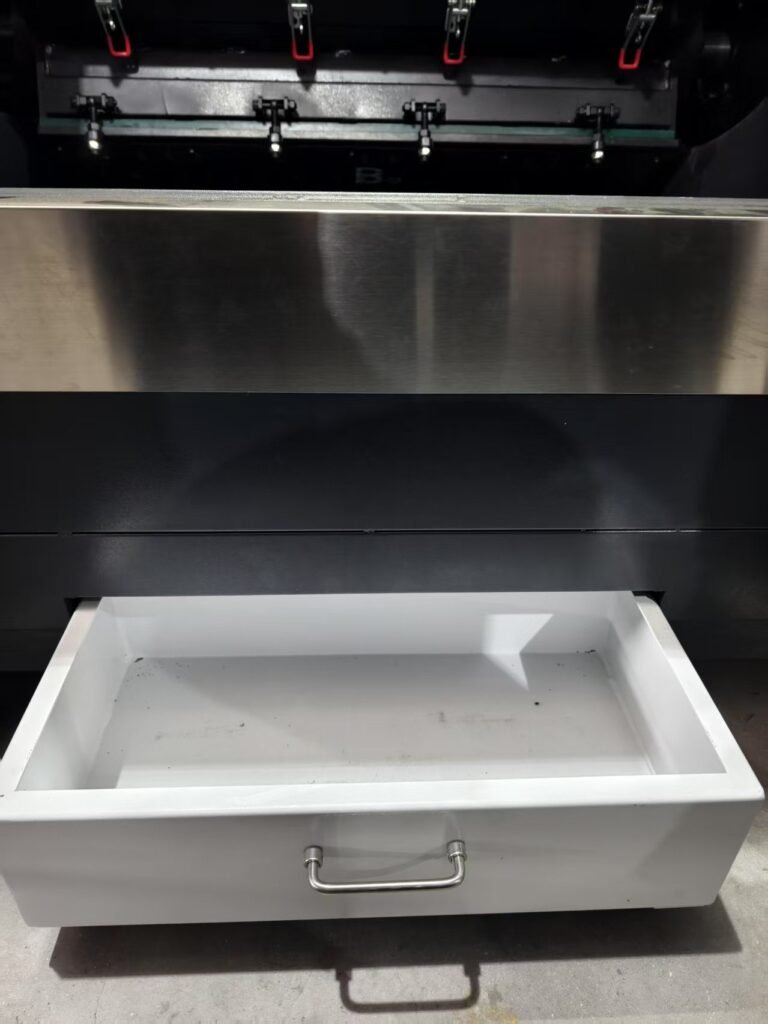

Bottom Dust Collection: A built-in dust collection box facilitates easy cleanup of polishing residues, maintaining a clean working environment.

Technical Specifications of Han Kun Machine

Voltage: 380V

Number of Barrels: 12

Total Power: 8.3kW

Noise : <80dB

Weight: 3500kg

Dimensions: 2650×1800×2100mm

Max Speed: 130 RPM

Production Efficiency: 12-288 pcs/batch

Barrel Dimensions: 1000×180×150mm

More Models Available